May 2, 2024

From infant care and virtual reality to art preservation and submarines, VCU Engineering students show off their creative problem-solving

Winners of College of Engineering’s annual Capstone Design Expo reflect dedication across an array of disciplines.

Share this story

For the past year, seniors in Virginia Commonwealth University’s College of Engineering have been working to make the world a better place for humankind.

Whether assembling a wheelchair-lifting system, constructing a hybrid bike for veterans with limited mobility or exploring safe human-industrial robot collaboration, the senior class unveiled their research projects on April 26 at the college’s annual Capstone Design Expo.

A signature event of the college, the expo represents the culmination of the graduating class’s education and showcases their innovative research and design prototypes from their yearlong senior Capstone Design course. The required class teaches leadership, teamwork and design skills.

Faced with challenges when developing prototypes, students gain valuable insights into the intricacies of designing innovative solutions. For many, the process highlights the importance of flexibility and adaptability in problem-solving.

The long-term nature of the projects sets this course apart from the rest of the curriculum. Students discovered the challenges of turning their initial ideas into a functioning product – and that building a solution is far tougher than designing it.

Here are summaries of the 2024 Engineering Capstone Design Expo winners.

BIOMEDICAL ENGINEERING

Mini Sensors to Track Movement of Preterm Babies (BE 24-103)

Ashlyn Jones, Ireleigh O’Malley, Sarah Johnson, Adriana Bautista and Ishika Singh (advisor: Thea Pepperl)

“Premies” — babies born prematurely — are more susceptible to health challenges and require constant monitoring. This project tracks newborns’ movements using sensors to identify any potential issues, such as neurological complications or infections. It aids in early detection, ensuring these babies receive care for optimal health and development.

“We faced challenges when prototyping and choosing the most suitable wearable design to meet our sponsor’s specifications, since we needed to ensure the sensor was protected, the device as a whole could be sterilized, and maximized the baby’s comfort,” Bautista said.

CHEMICAL AND LIFE SCIENCE ENGINEERING

Subcritical Hydrothermal Catalytic Degradation of PFAS (CLSE 24-204)

Abdullah Alqallaf, Jazzamine Threatt, Holly Sheppard and Anthony Anzelmo (advisor: Frank Gupton)

Poly- and perfluoroalkyl substances — commonly referred to as PFAS, or “forever chemicals” — take nearly forever to breakdown and, since they contaminate drinking water, can build up in the body over time. Forever chemicals are used to create common household products such as cleaning solutions, nonstick cookware and personal care items, and demand to find ways to break down PFAS is steadily increasing every year.

This project developed a continuous method of degrading PFAS found in water. Implementing two separate methods, the students removed up to 76.5% and 98.8% total PFAS, respectively, setting the stage for future experiments to see how adsorption affects the final concentration of PFAS in the treated solution.

COMPUTER SCIENCE

Sentiment Voice: Integrating Emotion AI and VR Performance in Arts (CS 24-319)

Josiah Wilson, Chase Taylor and Ariana Thomas (advisor: Alberto Cano)

Can artificial intelligence “read” people’s emotions when they’re inside virtual reality? The students developed a system using the Unity Platform that tracks a user’s emotional changes.

Based on what users say and how their facial expressions change, the environment — in this case, a computer-generated Tokyo — changes around them, showing how someone’s emotions can project into the environment around them.

Based on research by VCU’s Semi Ryu, Ph.D., the project offers potential in multiple settings, including treating patients with PTSD or helping users process trauma and stressful situations.

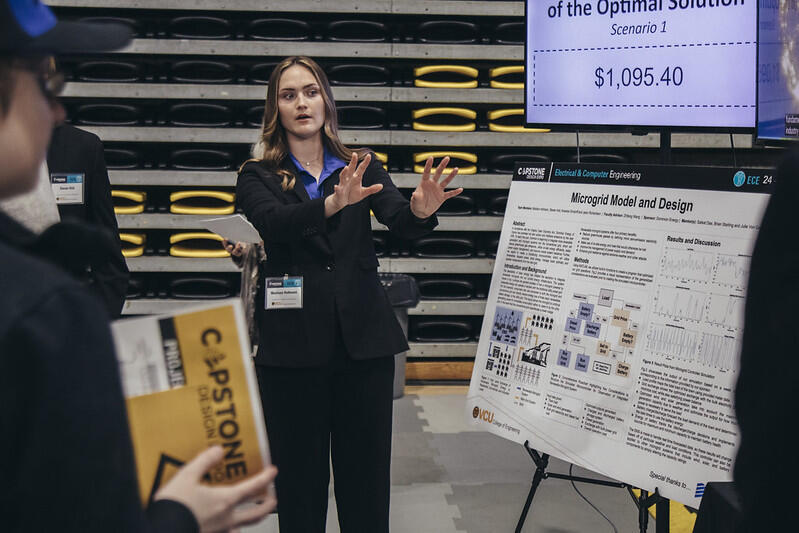

ELECTRICAL AND COMPUTER ENGINEERING

Microgrid Model and Design (ECE 24-405)

Madison Hofmann, Steven Holt, Amanda Orndorff and Jalen Richardson (advisor: Zhifang Wang)

Dominion Energy sponsored this project, in which the students designed an energy management system — essentially, a tiny computer controller that functions as a brain — to forecast electric demand. The “brain” helps decide how to use electricity most efficiently and at the best price by determining where the electricity should come from — the sun, the wind or a diesel generator.

As the world continues to shift toward renewable energy, the students wanted to think small (as in, microgrids) as well as big.

“Since microgrids rely on small, local generation, this makes them optimal for deploying renewable energy resources,” Holt said. “Implementing renewable energy throughout communities using wind turbines, rooftop solar panels and even solar carports reduces the need for large power farms that consume large amounts of land. Having power available locally also reduces stress on long-distance transmission networks and increases reliability in times of high grid instability. Ultimately, microgrids are an efficient way of implementing a sustainable, renewably powered future.”

MECHANICAL AND NUCLEAR ENGINEERING

Fabrication of Magnetic Filaments for Fused Deposition Modeling Technology (MNE 24-503)

Thomas Pierce, Micaiah Akyeampong, Vincent Mazzochette and Kamau Bey (adviser: Radhika Barua)

Additive manufacturing — building something by adding material one layer at a time — reduces reliance on traditional supply chains by enabling on-demand production of spare parts and components.

One of the most common methods of additive manufacturing is fused deposition modeling, better known as 3D printing, which extrudes a plastic filament in a series of layers to create the 3D object.

This team set out to produce a magnetized filament by combining recyclable polymer with magnetic powders and conductive fillers. Ultimately, the proposed filament could be used for 3D-printing electromagnetic shielding, which is used for applications such as surface ship radar, weather radar, air traffic control, inflight Wi-Fi and spacecraft telemetry.

MULTIDISCIPLINARY

VMFA Horizontal Track System (MULTI 24-618)

Cole Jordan, Zach Mazzola, Andrew Shalaski and Matthew Hayden (advisers: Reza Mohammadi, Dan Resler)

Art conservationists meticulously preserve and repair paintings that tie us to the past by using fine precision tools, including microscopes. But the risks – even just a minuscule flake of paint chipping off during movement or inspection – are high.

This group set out to design a track system to allow a microscope to travel over large pieces of art. Think of a claw machine at the arcade, where the claw can be positioned and then lowered – though in this case, the “prize” isn’t touched.

The current industry standard for such inspection costs hundreds of thousands of dollars. This system can be built in stages, starting with manual motion based on a system of rails and carriages — like a drawer — that can then be upgraded to automated motion with motors. It can be installed for about $8,500.

BEST INDUSTRIAL

Advanced Rudder Actuation (MNE 24-509)

Keely Cooley, Alex Sellers, Thomas Goldstein and Daniel Woodworth (adviser: Worth Longest)

Few modifications have been made to control systems in submarines over the past century, with new technologies having issues of scalability and cost. The team wanted to explore better maneuverability, stealth and efficiency of submarines.

After creating more than 15 novel rudder and control designs, the team chose the top three for further analysis: a whale-inspired tubercle design, a triple-hinged flap and a compliant mechanism design. The students then prototyped and tested each design in a wind tunnel, comparing the results with a control test sample and to each other. The major measures of success were maximum lift-to-drag ratios of hydrofoils, minimal acoustic effects and signatures, and robustness of the design.

Preliminary results showed that while the whale tubercle design acted as intended, a few changes to the design could have increased the lift-to-drag ratio in comparison with the control sample. Analysis is still underway for the compliant and segmented hydrofoils, which are expected to perform better than the tubercle design.

EXCELLENCE IN DESIGN

Design to Reduce Pulse Oximeter Reading Inaccuracies Due to Skin Pigmentation (BME 24-107)

Jayla Johnson, Ellen Patchin and Mariana Fernandes Gragnani (adviser: Barbara Boyan)

Patients of color often receive delayed oxygen treatment due to inaccuracy in readings from the pulse oximeter — the device that clips on to a finger to measure oxygen in blood. Current models report a larger number than usual, which can be dangerous as doctors don’t realize the patient actually needs more oxygen.

The students developed a new oximeter that improves how it measures the oxygen in blood, regardless of skin color.

“Health care has a long history of racial and gender-related disparities that have long affected the quality of treatment many individuals receive,” Pathcin said. “This has taken the form of issues like the one our project addresses, where the technology itself is not suited for darker skin tones, and medical practices founded on misinformation and medical myths.”

PEOPLE’S CHOICE

Formula SAE Aerodynamic Front Wing Design (MNE 24-516)

Carson Clark, Jonathan Morton, Garrett Giddings and Ryan Noll (advisers: Bradley Nichols, Laleh Golshahi)

Ram Racing, the multidisciplinary student organization that designs, builds and races Formula 1, Formula E and Mini Baja race cars from scratch, wanted to improve the performance of its next race car.

Members of this project group who have experience racing the car have noticed a serious performance problem when the car enters a corner. The car lacks traction at the front wheels and slides, rather than turns, when cornering, which slows its speed in that part of the racecourse.

Speaking to other FSAE race teams from other Virginian colleges, the Capstone team learned that many race teams have little to no background research or analysis for their front wing design. The student team designed a two-foil front splitter for a Formula SAE car to produce maximum downforce while maintaining laminar flow over the front tires.

“It’s the opposite of an airplane wing,” Noll said. “Instead of lifting the plane up, it forces the car down.”

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.