Nov. 4, 2011

VCU Researchers Develop a Hemostatic Bandage

Unique technology may one day help troops on the frontlines

Share this story

What started as a nonwoven fiber mat composed of tiny fibers measuring just a few nanometers in diameter has been translated into a unique material that can stop massive bleeding in a short period of time – possibly one day saving the lives of severely wounded soldiers on the frontlines of combat.

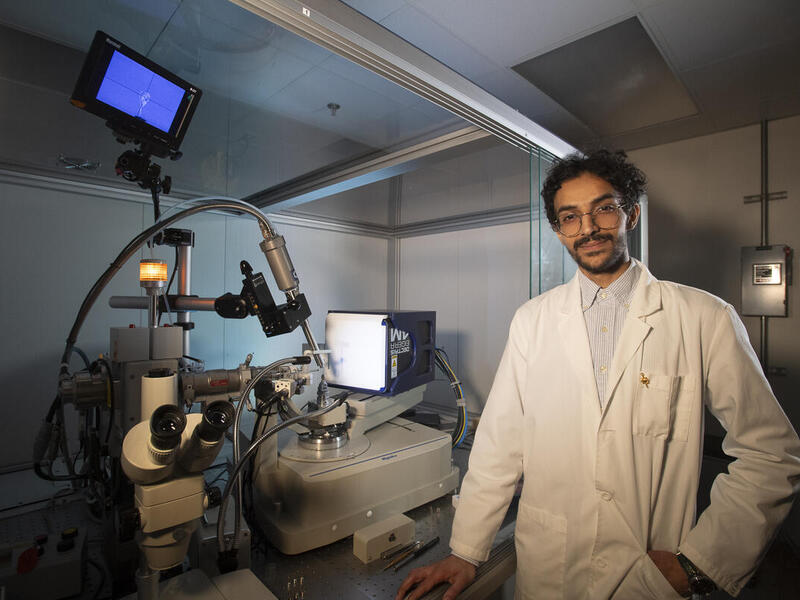

By “spinning” the right mix of engineering, biology, medicine and life sciences together, Gary L. Bowlin, Ph.D., professor of biomedical engineering in the Virginia Commonwealth University School of Engineering and director of the Tissue Engineering Laboratory at VCU, and David G. Simpson, associate professor of anatomy in the VCU School of Medicine, created a hemostatic bandage – composed of resorbable materials that rapidly stop massive bleeding by the induction of a clot.

“Often in military situations, there is so much blood loss involved and anything used to try and stop the flow can get diluted and washed out quickly - never having the chance to form that necessary plug to stop the bleeding,” Bowlin said.

“We needed to concentrate on those critical factors for the bandage – it had to be placed locally and be effective. Most technologies that are used now must be cleaned out and removed because otherwise they cause a massive inflammatory response,” he said.

The material used to create the bandage, described by Simpson as being “like cotton candy with coagulation properties rolled into it,” grew out of their research on electrospinning – a process that comes from electrostatic spraying – which has been described in the scientific literature as far back as 100 years.

Bowlin and Simpson were first able to create nano- to micron-scale biomedical fibrous structures using the electrospinning process more than 10 years ago. Electrospinning involves a charged polymer solution being shot through a needle or pipette tip towards a grounded collecting plate. The solution evaporates during travel toward the collecting plate leaving a continuous polymer fiber that is collected as a non-woven fabric on the plate. Bowlin and Simpson adapted this technique for use in the fabrication of templates to promote normal tissue regeneration.

When Bowlin and Simpson started thinking about formulations and examining different variations of materials, one of the challenges they faced was to find materials that could be reabsorbed by the body. That’s when they decided to go back to basics and examine what the body naturally uses to clot and what would be absorbed by the body. To create the novel hemostatic bandage, they took a sugar that is synthesized from sucrose called dextran, and formed a cotton ball from it using electrospinning. The dextran cotton ball became the delivery vehicle because when put into water it disintegrates almost instantaneously. Next, Bowlin and Simpson loaded the structure with salmon fibrinogen and thrombin – naturally occurring proteins used in the clot formation.

The final formulation was sent to the Armed Forces Lab for testing, and in 2010, the invention was licensed through VCU Tech Transfer Office to a start-up medical device company called St. Teresa’s Medical Inc. of Bloomington, Minn. The company is doing further testing on a finalized first product specification and conducting pre-clinical trials. Once the trials have been completed, the bandage will be headed for Food and Drug Administration approval. The company plans to launch the bandage as WRAPCLOTTM and market it to military and civilian traumas.

Bowlin and Simpson have continued to collaborate on work related to tissue engineering and their next steps will focus on the development of muscle for cosmetic and preferably functional repair of ballistic injuries incurred on the battlefield.

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.