Jan. 10, 2018

Course offerings, gift from Rockwell Automation, help VCU students prepare for major workforce need

Share this story

Courtesy photo

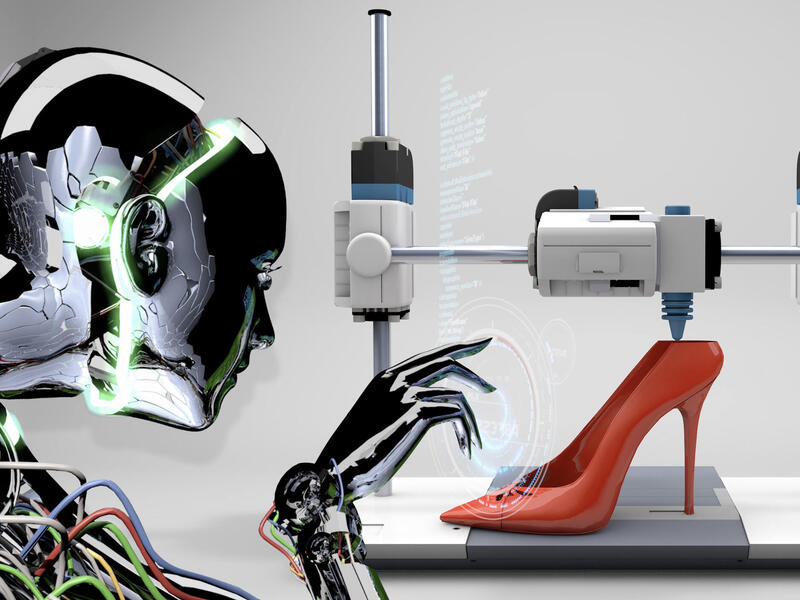

The Virginia Commonwealth University School of Engineering is expanding its curriculum and resources to prepare students for a critical workforce need: automation and controls engineering. A gift from Rockwell Automation — the second in two years — has provided classroom workstations to support instruction in this key area.

Automation and controls engineers design and optimize the computer-based systems that run industrial machinery and manufacturing processes. Robert Klenke, Ph.D., a professor in the Department of Electrical and Computer Engineering, said the decision to add two courses in controls engineering was made three years ago.

“We wanted to meet a need for the local business community, so Philip O’Connor [the school’s corporate and alumni engagement officer] put together a meeting with representatives from some of the main companies,” Klenke said. “Rockwell wanted to see us move this area forward and made an initial donation of workstations.”

Rockwell Automation, a Fortune 500 company and provider of industrial automation products, viewed the new courses as an opportunity to help address a growing skills shortage and partner with VCU, said John McSorley, a sales manager with the company.

“Globally, manufacturers are seeing hundreds of thousands of manufacturing jobs going unfilled because of the technology skill gaps,” he said. “This is an evolving field that serves industries including power generation, food and beverage, automotive, oil and gas, chemical and maritime, to name a few.”

Using the Rockwell Automation workstations, VCU students can set up programmable logic controllers, the specialized computers that operate industrial machines. PLCs are like traditional computers in some respects, but are far more rugged and vary widely in dimensions — from pocket- to room-sized. Klenke explained that PLCs use ladder logic, a programming language based on symbols, not words. The symbols are connected by lines representing electric current, so a finished program resembles a ladder.

One reason companies are so interested in students trained in this area is that it’s a different thought process.

“One reason companies are so interested in students trained in this area is that it’s a different thought process,” Klenke said. “Programming a manufacturing machine is very different from programming a process in a car or a plane. It’s interesting to see students go through a process and figure it out via ladder logic.”

Rockwell’s initial equipment donation two years ago could serve about 20 students. When demand for the course doubled last year, the manufacturer responded with an additional donation.

“This gift brings us up to a total of 11 stations, which has really expanded what we could offer students,” Klenke said. “With the 11 stations, we can now accommodate 44 students in the class.”

Josh Kirkham is one of the students already seeing the benefit of these courses. After earning his B.S. in electrical engineering at VCU in 2016, he began work as an electrical engineer with the chemical manufacturer Ashland Inc. Kirkham said the hands-on training in Klenke’s courses gave him an edge when he entered the workplace.

“Most engineers go through some form of text-based and function block diagram programming, but also being exposed to ladder logic in the PLC classes has been a huge help,” Kirkham said.

Using the Rockwell Automation equipment in his controls courses made it easy to see how everything was connected in the huge systems of an industrial facility, he added.

“Without that,” Kirkham said, “I would have had a lot of trouble visualizing how this was done in the plant where there are millions of feet of signal wire across acres of process equipment.”

Subscribe for free to the VCU News email newsletter at http://newsletter.news.vcu.edu/ and receive a selection of stories, videos, photos, news clips and event listings in your inbox every Monday and Thursday during the academic year.

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.