Nov. 20, 2025

VCU’s new Green Labs program mixes science and sustainability

Share this story

Danny Muñoz is facing the cold, hard facts – cold as in minus-80 degrees, and hard as in hundreds of those readings.

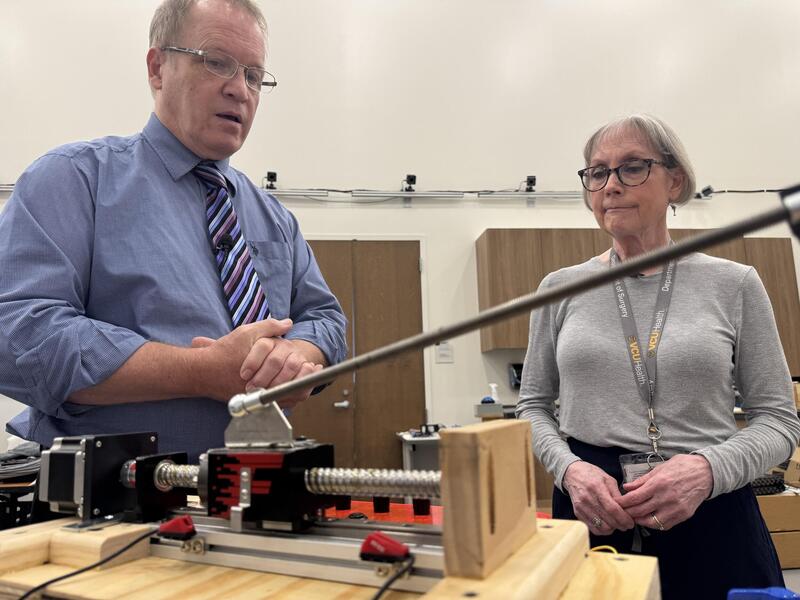

Muñoz is Virginia Commonwealth University’s director of environmental health and safety, and his work includes ensuring that laboratory research on both campuses follow proper safety protocols – and not just for humans. He and his team are key players in a new initiative, the Green Labs program, that aims to make VCU’s groundbreaking research as safe for the environment as it is for faculty, staff and students.

Among his team’s targets: hundreds of ice-cold freezers and fume hoods, and even thousands of stored chemicals.

Green Labs is a new part of the One VCU Sustainability Plan, which was adopted in 2024 as a first-of-its-kind plan for VCU to embed sustainability throughout the academic and health system realms. Sara Q. Barton, interim director of VCU Sustainability, said refining lab processes and procedures is key to reducing energy consumption and waste.

“Labs can be resource-intensive spaces, often requiring more energy and producing more waste than a classroom or an office,” she said. “The Green Labs program provides lab personnel with ways to integrate sustainability into their day-to-day operations, helping reduce the environmental impact of their labs.”

Here are some of the ways VCU is proceeding.

For freezers, it’s degrees of improvement

Environmental Health and Safety is bundling up for an effort that offers a bundle of potential savings: the Ultra Low Temperature Freezer Initiative. Consider these points:

- An ultra-low temperature freezer can use as much energy as the average household.

- VCU has more than 300 freezers on its campuses – and laboratories can account for more than 60% of a major research university’s energy consumption.

- Historically, deep freezers operate at a temperature of minus-80, but there’s an abundance of data to support that lab samples will remain safe and stable if the freezer’s temperature is raised to minus-70 – with the 10-degree adjustment offering major savings of energy and money.

Muñoz and his team, which took inventory of every lab on campus that had a minus-80 freezer, brought their idea to VCU’s Institutional Biosafety Committee, which consists of research faculty. The IBC, which reviews and approves protocols involving biological material, embraced the idea.

Muñoz also sought input from researchers who would be impacted by the new initiative, emphasizing that they are partners with the VCU administration in promoting sustainability.

“Our researchers on campus actually have to implement these changes, so it cannot feel forced,” Muñoz said. “If we expect them to follow through, we need their buy-in.”

Opting into the freezer initiative has also been voluntary. For example, if a lab has been working on a project for 20 years and has countless samples, the leaders might not want to change their storage protocols.

“So we suggest it, and we tell them what the literature says – but ultimately they get to decide if that’s too uncomfortable for them,” Muñoz said.

Rebecca Heise, Ph.D., chair and professor in the Department of Biomedical Engineering, said her transition was easy, and the deep freezers seem to run better at a higher temperature.

“Our samples have been doing fine, the freezers are performing better, and it’s better for the environment,” she said.

Helping fume hoods go with the flow

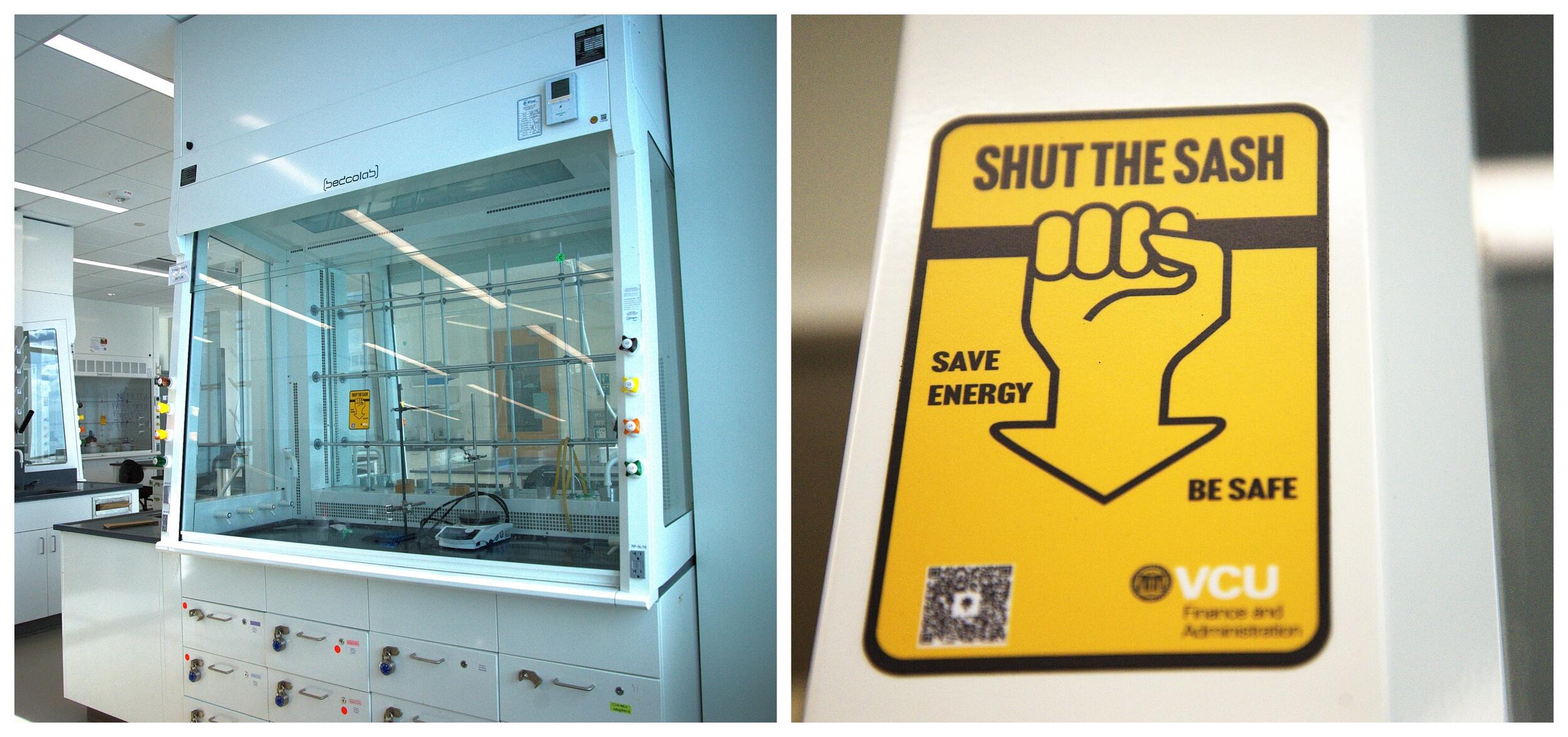

Laboratory fume hoods are enclosed ventilation devices with sashes that allow one or more sides to open. They capture fumes, vapors and gases from chemicals, allowing the dangers to be removed without exposure to researchers.

As part of Green Labs, the Fume Hood and Safety Efficiency Program will cover a lot of ground. Consider these points:

- Fume hoods can use as much energy as 3.5 homes per year when left running 24/7.

- VCU has nearly 700 fume hoods across both campuses.

Muñoz and his team are taking inventory of the fume hoods to identify the newer, more efficient models and the others that are candidates for replacement with energy-saving value.

Traditionally, VCU focused primarily on whether a fume hood was operational or not. But now, managing airflow, within a safe range, is considered a priority to help make the labs more energy-efficient. Muñoz noted that the goal is to be more efficient with energy use while ensuring the equipment still performs as it should.

The inventory is progressing, with the team hoping to visit every lab on campus by the end of the year.

Taking account of chemicals

While some VCU labs have only a single shelf of five chemicals to track, others have thousands – and it can be a challenge to know what is or isn’t in stock. Green Labs is addressing the need through its Chemical Inventory Management and Waste Minimization initiative.

Muñoz cited a common situation: A student needs a specific chemical, checks a closet, can’t find it – and orders more. Meanwhile, there already are five bottles of that chemical in storage.

Now VCU is having labs use SciShield ChemTracker, an inventory management system. Researchers are required to update their inventory at least annually, and the system will track what is in stock and, notably, where it is.

Keeping track of the chemical inventory also helps labs reassess what they still need and safely dispose of what they don’t.

“Also, from our perspective, [SciShield] allows us to know what health and safety risks are in all of our labs,” Muñoz said. “So if there is a spill or a fire, we can look at the chemicals involved and safely determine the best way to approach the situation.”

“Our researchers on campus actually have to implement these changes, so it cannot feel forced. If we expect them to follow through, we need their buy-in.”

Danny Muñoz, director of Environmental Health and Safety

On the horizon: the tools of chemistry

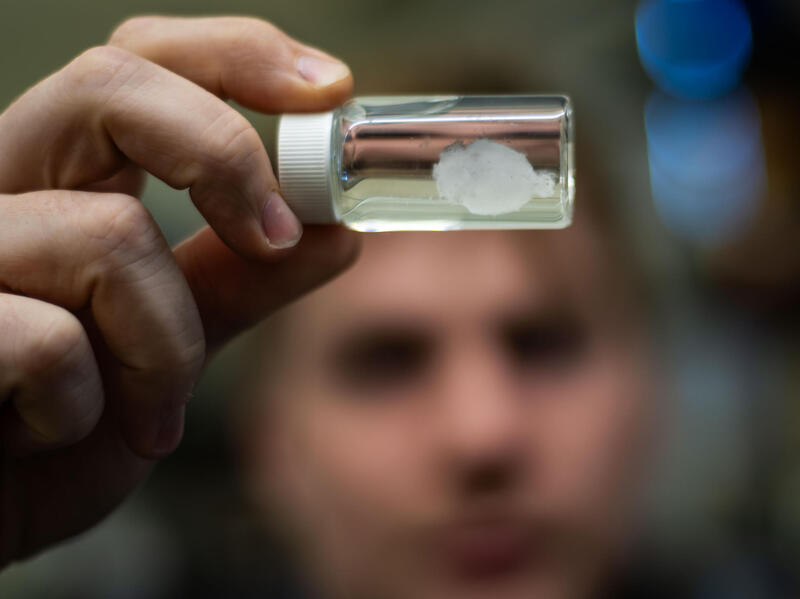

Green Labs is also considering another initiative – microscale chemistry.

Historically, labs used larger quantities of chemicals so they could easily see and measure reactions from start to finish. With improved technology and far more sensitive instruments, labs no longer need those amounts, and Muñoz said they can now consider transitioning to microscale work.

“We are not asking anyone to change the chemistry or the process,” he said. “Simply reduce the amount. Trade the one liter setup for a 500 microliter setup.”

While such a change may seem simple, Muñoz noted that labs would need to buy all new glassware, which is a major commitment. But he said such a change could dramatically reduce the volume of chemicals on campus.

“What we’ve been communicating to our researchers is we’re not trying to stop you from doing the work you’re doing,” he said. “We just want to help you do it safer and more efficiently.”

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.