Nov. 24, 2014

Saving football

Share this story

Football fans know well how it looks and how it sounds. From just off screen or just out of sight there is a flash followed by a pop. Helmets collide.

Sometimes the player or players rise immediately from the turf and fans never know those involved were knocked unconscious or sustained a concussion. In the worst cases, players go limp, seemingly lifeless, or they go stiff, resembling rigor mortis.

It was one of these gruesome scenes playing out repeatedly via instant replay one Sunday afternoon in November of 2013 that led Ray Colello to start thinking about a solution.

Being an associate professor in the Department of Anatomy and Neurobiology at the Virginia Commonwealth University School of Medicine, Colello has a genuine concern and unique perspective about the injuries these players and others around the country at all levels of play sustain every week.

So sitting in his recliner that day, Colello began to search for possible answers. However, he isn’t a physicist, so understanding how to mitigate these high-speed collisions was at first a simple daydream.

He thought about practical solutions as well as outlandish ones, like giant helmets. “You start to free associate as a scientist,” he said.

In a moment of science fiction digression he said to himself, “Each player just needs a force field.”

Soon thereafter, as he walked to the kitchen for a beverage, Colello studied all of the homework, test grades and artwork secured to the family refrigerator, and suddenly that force field idea didn’t seem so out of reach after all – and it wasn’t science fiction that could make it possible, it was far simpler than that.

It was magnets.

“You obviously don’t want two guys with opposite poles attracting to each other, stuck together all the time,” Colello said in a recent presentation. “But we’ve all played with magnets, and if you take magnets with like poles – two positives or two negatives – and try to push them together you’ll see that they have a repulsive force.”

That repulsive force in magnets, Colello hypothesized, could be applied in football helmets to slow down force, essentially putting a break on the impact before it occurs.

Surely, he later thought, an idea this simple, this seemingly obvious, had been tried before. What he found though, after checking with the university’s resources on patent issues at VCU Innovation Gateway, is that it hadn’t.

A nationwide problem

There are more than 1.1 million football players nationwide in high school, college and the National Football League. Among them, roughly 100,000 concussions occur each year, 60 percent of which are the result of head-to-head collisions.

Concussions are minor traumatic brain injuries that can lead to headache, changes in alertness or loss of consciousness. They occur when the brain makes impact with the skull or cranium.

Research has shown that repetitive brain trauma, such as concussions, has led to Chronic Traumatic Encephalopathy in football players, boxers and other athletes. CTE is associated with memory loss, confusion, impaired judgment, impulse control problems, aggression, depression and progressive dementia.

Football players experience 500 to 600 helmet-to-helmet hits each year. Measured in G-force, the collisions range from 5 Gs or 10 Gs up to 150 Gs or 160 Gs. Concussions begin to occur at 100 Gs.

Most concussions occur not in the biggest players, but in players like wide receivers and cornerbacks who are faster and have more space in which to accelerate, and the result of that acceleration is what Colello said is the key to the problem.

“It’s the sudden deceleration the brain experiences within the cranium at impact as a football player running at up to 20 mph is stopped within 10 to 15 milliseconds,” he said.

A garage and a bathroom scale

After his refrigerator-induced epiphany, Colello was downright giddy.

“I was stoked,” he said. “I remember waking up the next morning – after I knew strong enough magnets are available – I was so stunned and I thought ‘This is it, I’m going to do this.’”

“I have funds from the NIH and another granting body to look at spinal cord injury,” he said.“But I had absolutely no money to do modifications to football helmets. So I talked to my wife, Jenny, and told her I had this idea. ‘What do you think, can I use the credit card? No more than about $1,000.’”

She said yes, so Colello took to the garage.

He used the money to invest in neodymium magnets, which are the strongest type of commercially available permanent magnet. Called rare earth magnets, they’re made of alloy of neodymium, iron and boron.

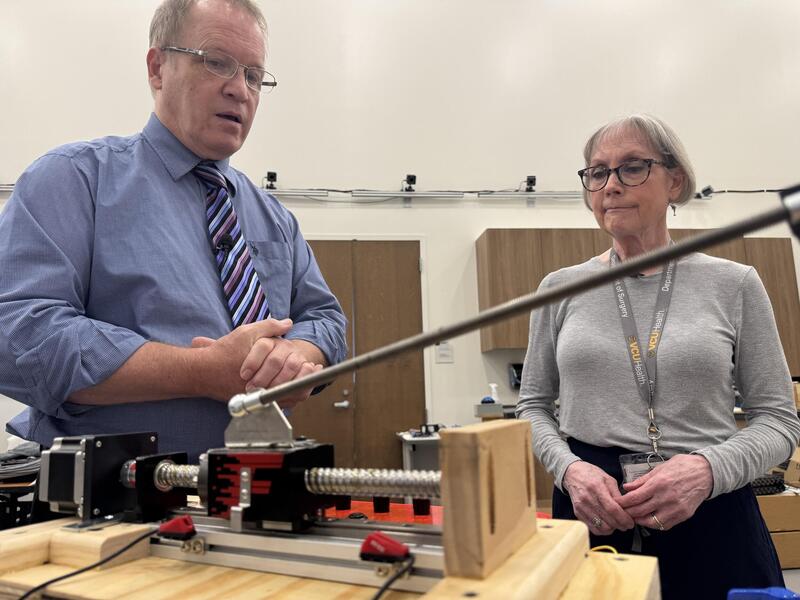

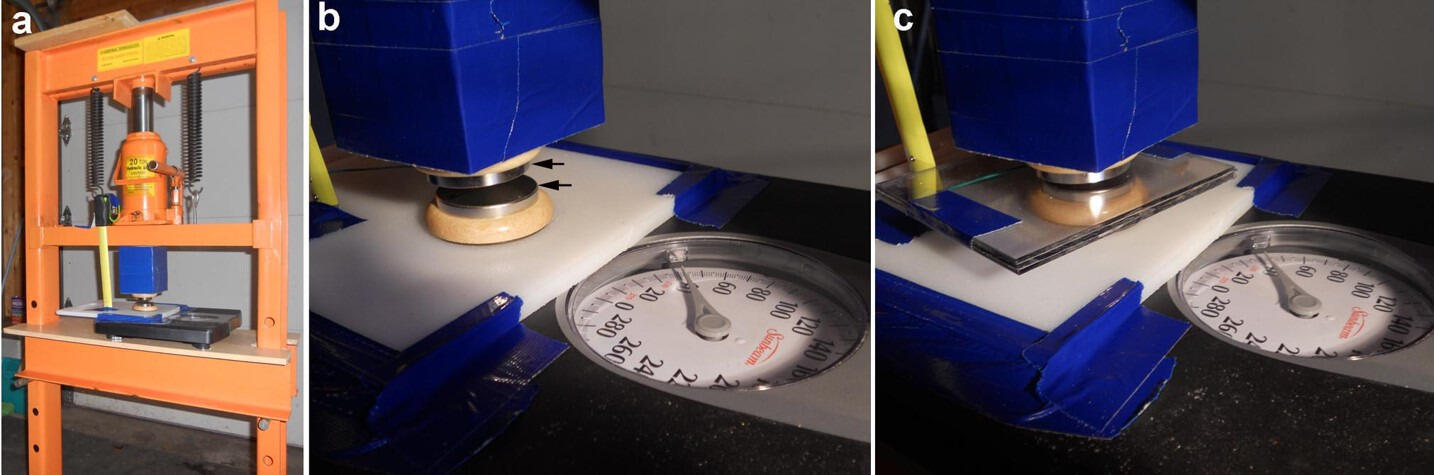

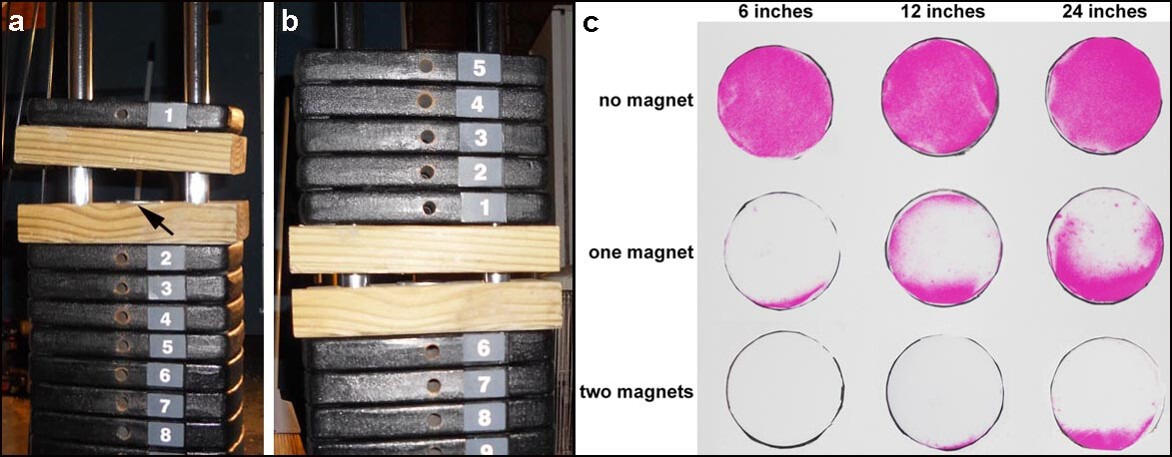

With the help of his wife and son, Ian, Colello attached opposing magnets to blocks of wood and put them on his bearing press, a car mechanic’s tool he has for inserting bearings into wheel hubs. To measure exerted force as the magnets were slowly pressed together, he used a scale from his bathroom.

He found that at an inch away from one another, the magnets exerted little repulsive forces, but at a quarter of an inch away, single opposing magnets exerted more than 60 pounds of force. When he doubled the magnets, that force rose to more than 120 pounds.

“That looked really promising and I thought, ‘Wow, this really has quite a bit of strength,’” he said. “But I wanted to add the acceleration component to this.”

The bearing press created a slow, controlled force, but what, he thought, could more accurately represent the impact of a football collision?

He didn’t have to look far to find his personal weight set.

In a manner similar to the weight drop assay used by helmet manufacturers to test helmet safety, Colello dropped a 10-pound weight, with or without magnets, from varying distances and used pressure-sensitive film that is normally used in automotive work to measure the results.

Again, Colello’s rudimentary tests proved fruitful, showing that the magnets drastically reduce G-forces when acceleration was taken into account.

That’s when he realized he might really be on to something, so Colello went to VCU Innovation Gateway, which facilitates commercialization of university inventions, and filed for a provisional patent Feb 16.

He also applied for and was granted a VCU Presidential Research Quest Fund award, which each year affords all faculty internal funding opportunities for support of new, emerging or continuing research. A collaborator on the grant was John Speich, Ph.D., associate professor of mechanical engineering in the VCU School of Engineering.

With the $50,000 he received from the Quest Fund, Colello could afford new tools, such as an accelerometer, to substantiate his earlier findings.

What he found was that, in the absence of magnets, a 10-pound weight dropped at 24 inches could generate 65 Gs upon impact. With magnets, the impact was reduced to 17 Gs. Similarly, the same weight dropped from 48 inches produced 120 Gs in the absence of magnets, but only 88 Gs in the presence of magnets, which is well below the threshold for concussions.

The G-force is reduced because the time of the collision is increased by milliseconds.

Colello uses an analogy of tossing a baby in the air. Catching with stiff arms will create a short hard jolt, but allowing the arms to give way in the catch increases the length of the collision and thus isn’t bothersome.

Chris Johnson, one of the fastest players in the NFL, has run the 40-yard dash in 4.24 seconds, reaching 19.3 mph. At that speed, a collision that lasts 12 milliseconds produces a G-force of 120, but if that collision is drawn out to 17 milliseconds the G-force drops to 84.

“What we’re doing is dramatically shifting the curve,” he said. “Remember, 100 (Gs) is where concussions readily occur. If we can shift to the lower side of that number it should reduce the amount of concussions on the playing field.”

A new approach to an old problem

Ongoing changes and innovations over the past several decades aimed at reducing the prevalence of concussions have failed as the number of concussions in football continues to rise.

“Everybody who works on football helmet design does the same thing,” Colello said. “It’s to reduce impact forces after the collision has already occurred. They say, ‘Alright, the collision has occurred, can we displace the energy in some manner?’”

They’re still going to make contact, but it’s like driving your car into a wall at 30 mph versus driving your car into a wall at 30 mph, but hitting the brakes right before you make contact.

The traditional approach helmet manufacturers are taking is to disperse, displace or absorb the energy using special helmet materials and air- or foam-filled padding inside the helmet.

Colello’s idea is to supplement these methods.

“Our approach aims to add something completely different,” he said. “That is to put a brake on the impact before it even occurs.”

“They’re still going to make contact, but it’s like driving your car into a wall at 30 mph versus driving your car into a wall at 30 mph, but hitting the brakes right before you make contact.”

A prototype and more homemade tricks

In the coming weeks Colello will stuff rented crash-test dummie heads into prototypes of his helmet, attach them to a zip line hung between two telephone poles on his farm, and crash them into one another.

He hopes to show again what he has seen in previous tests, which is that the magnets will reduce G-forces in direct impact. What he also hopes to find, though, is that the magnets will have a deflecting effect as helmets will slide off of each other more than before.

Colello’s prototype will be the result of a truly interdisciplinary effort.

The magnets need to be custom ordered so they fit perfectly into the helmet’s arch, but what are those measurements?

Colello used putty and a pad-less helmet to make initial molds that fit the helmet perfectly, and then worked with Bernard Means, Ph.D., instructor of anthropology in the VCU School of World Studies, on a specialized computer program to determine the exact measurements of that mold.

Next, he sought out the help of the top-ranked VCU School of the Arts Department of Sculpture. Third-year student Christina Delli Santi created the molds that were used to finalize measurements and orders.

If it all goes according to plan, Colello expects his helmet to be very close to usable since his design will meet all criteria provided by the NFL as they look for a concussion solution. The criteria are as follows.

1. Helmet cannot affect the look, style and intensity of play.

– The decreased G-forces observed in Colello’s research occur in the final milliseconds before impact and would be imperceptible to the human eye.

2. Helmet should not dramatically affect the dimensions and look of the standardized helmet design.

– Colello’s magnets will be form-fitted to the curve of the helmets and placed between the plastic shell and the padding.

3. Helmet should be able to integrate in existing football helmet designs with minor modifications and within one to two years.

– Colello’s research has moved quickly thus far, and the crash test dummie heads are on their way.

4. Helmets should be cost efficient and adaptable for play at all ages

– Colello’s helmets will include three magnets covering the areas of the head where 64 percent of helmet-to-helmet collisions occur (one over the forehead and one on each side of the head) at a cost of $35 each. Helmet prices today are between $150 and $400.

5. Helmets should reduce the prevalence of concussions on the playing field.

– So far, G-force measurements show this will be the case in Colello’s helmets.

Subscribe for free to the weekly VCU News email newsletter at http://newsletter.news.vcu.edu/ and receive a selection of stories, videos, photos, news clips and event listings in your inbox every Thursday. VCU students, faculty and staff automatically receive the newsletter. To learn more about research taking place at VCU, subscribe to its research blog, Across the Spectrum at http://www.spectrum.vcu.edu/

Subscribe to VCU News

Subscribe to VCU News at newsletter.vcu.edu and receive a selection of stories, videos, photos, news clips and event listings in your inbox.